This gate is going to be fundamentally the same style with the addition of the opening for my plus sized cat. She still fits through the front gate I made almost five years ago but it's a bit of a squeeze. I wouldn't be shocked to find her running through the house with a gate stuck around her waist.

Sunday, June 18, 2023

New Baby Gate Plans

This gate is going to be fundamentally the same style with the addition of the opening for my plus sized cat. She still fits through the front gate I made almost five years ago but it's a bit of a squeeze. I wouldn't be shocked to find her running through the house with a gate stuck around her waist.

Sweet Alexandria (Lexi)

I got another puppy...

Picture Frames

Over the winter I made a couple of picture frames out of some soft maple I got a few years ago for free. I have a lot of the maple so I used a little bit of it to make the frames. I needed to wait until the weather got good enough to put finish on them.

Well, they got their finish, had the art put inside and have been hung on the walls.

The art is some water colors we bought from an artist on a trip to Saint Marten many years ago. Fortunately we stored them safely so they weren't damaged but unfortunately it took me over ten years to make the frames so we could appreciate them on our walls.

Hopefully the first couple of many more pictures to be framed and hung on my walls.

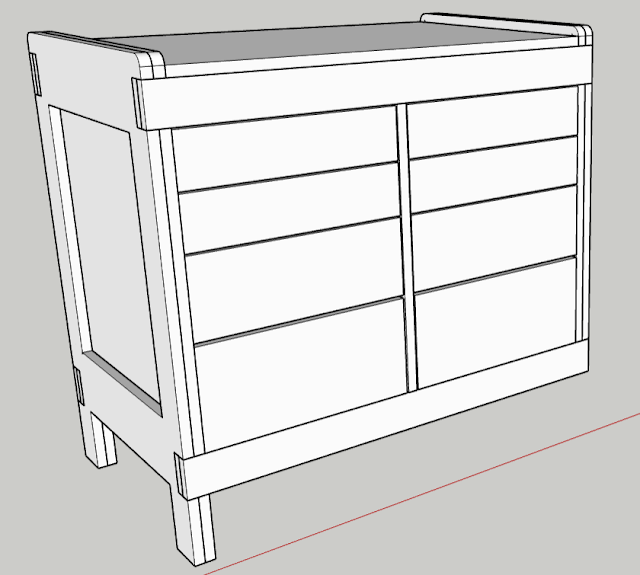

Radial Arm Saw Mobile Cart Progress

If you only count hours in the shop I've been making good progress on the Radial Arm Saw Cart. If you go by calendar it hasn't been that great. Regardless, last weekend I got the panels shaped.

My first step was to shape the tall outer panel as seen below.

|

| Tall Panels |

I cut the first rail slot by hand but then I got a little smarter and made a jig. I took one of the longer rail offcuts and cut it into three pieces. I then glued them back together to make a router template. To cut the rest of the slots in the panel I carefully measured, clamped the template in place, removed most of the waste with my jig saw, then trimmed to the exact size with a half inch pattern bit in my router.

|

| Short Panels |

|

| Middle Panel and extra support rail |

My first task this weekend was to drill the holes for the handles. I'd bought 1" black pipe for these and fortunately I thought to measure it. It's 1" inner diameter so the actual outer dimension was about 1-5/16". I don't have a Forstner bit that size so I just used a 1-3/8" bit. They'll be a bit loose but that's better than being too tight or not fitting at all.

|

| Tall side panel glue up |

I did use a lot of clamps gluing up the two side panels. I may have had the nailer ready but I didn't have any cauls ready. I did have the rails for the cart though so I used a couple of them to try to spread pressure across the panel. I noticed I didn't have any glue squeeze out on the bottom though so I took the other two rails and used them to put some pressure more in the middle of the panel. It isn't pretty but it worked.

As you can see from the above photo I needed a cross clamp to bring everything square but it was pretty close regardless. This was just making a very slight adjustment.

I glued up a couple of blocks to support the wheels, again sanding the finish where they were glued on. I intentionally left them a bit short of the rail so when I add drawers I'll have space to add the drawer rails.

And voila, done except for drawers I will add much later and a top.

And with the top...

I was intending to make the top out of a singe piece of wood/plywood but I happened to have two pieces of scrap panel that I could cut down and only "waste" a little bit of wood. I figured it would work as a temporary top and if it doesn't work I'll replace it later.

I had my neighbor - we'll call him Steve to protect his identity - come over and help me lift the saw onto the cart.

It still needs drawers and a table for the saw but at least it is up off the ground and is on a cart that will be easily mobile. I planned on putting adjustable feet on the leg side. I think I am going to wait a while before I put them on though. It seems to sit pretty stable so far.

I intended on putting of drawers for a while but then I came across a recycle bin full of accessories for the saw. I don't know when I am going to use them but it would probably be best to keep them with the saw. Maybe I'll add a quick shelf and see if I can fit the bin underneath.

We'll see... For now, it is done.

Friday, April 7, 2023

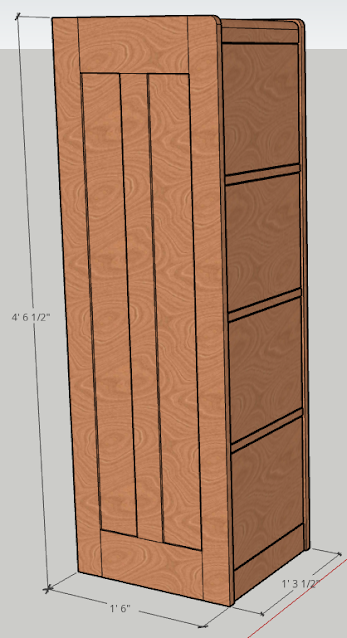

More Sketchup - Four Drawer File Cabinet

It is hard for me to get into the workshop during the week which is sad. However, doing design scratches the same itch as making sawdust for me. When I was learning to fly my instructors would call it chair flying. Basically, sit yourself in a chair and go through all the steps involved in starting, taxiing, and flying the plane. This is the same thing for me except I am building projects in my head. I am thinking about joinery, order of operations, etc.

I did design wheels for my tool cart.

They aren't perfect in every detail but they serve the purpose I needed. I'm tempted to go back in and make them more accurate as an exercise but I think I need to get a little better with Sketchup first.

With that done I remembered the other project I wanted to make. My in-laws had this beautiful quarter sawn white oak four drawer file cabinet. Unfortunately it has seen better days. The finish went bad and it suffered some water damage causing the veneer to buckle and separate. I briefly thought about trying to clean it up; however, I'm pretty sure building a new one will be less effort. So, I am going to design and build my own four drawer file cabinet.

A file cabinet is just another case of drawers. It shouldn't need anything too fancy. Sure it is going to get filled with hundreds of pounds of paper but does that really differentiate it from a bookshelf when just considering the case? I don't think it does.

I started my design with the drawer. Since the drawers need to be a specific dimension in order for the hanging file folders to work my drawer width is already fixed for me. I did decide that I wanted my cabinet to be 18" deep so that meant 16" drawers to leave room for the false fronts and cabinet back.

I'm going to hang my drawers on 16" full extension side-mount metal slides. These are easy to mount and should be plenty strong. I will not be opting for the soft close style.

Those slides look a little stubby because I could only find 24" and 14" slides in the Sketchup collection. 14" slides were sufficient to get the idea across and to help measure/fit the width of the cabinet. As you can see in the above photo I have a 16" deep drawer made from 1/2" material. The false front is 3/4" and is sized to leave a 1/8" gap all around. The 1' 1" width measurement is including the sides so there is 12" between rails.

The rails are 1/2" x 1/2" angle aluminum. I'm going to attach it to the top of the drawer sides using screws and epoxy.

With my drawers figured out I moved on to spacing them out. I put a 3" toe-kick on the bottom, added a 3/4" divider between each drawer, added a 1/8" gap, and topped it with a 2" thick top. Here's an image with one side and the back removed so you can see the internal structure.

You can see I left plenty of room for the 1/4" plywood back. I haven't included the rabbets for the back in the Sketchup yet and I don't know if I will. So long as I remember I need to do it when I am doing the construction it should be fine. Same reason I don't have joinery on the drawers yet. I haven't determined what material I will make them out of which may influence the type of joinery I will use.The stiles are going to be 2 3/4" wide. Both the top and bottom rail are going to be 5". In the above image the stiles are actually 3" wide but I thought they looked too big as they only leave 4 1/2" of panel. I'm going to shrink them to 2 3/4" which makes the panels 4 7/8" wide. This makes the panels twice as wide as the stiles vs only one and a half times as wide.

Building the Rolling Tool Cart

It still needs some work but I got most of it done. I cut out the middle and the bottom using my cordless Makita circular saw. I used my homemade fence to layout and guide it and needed to plunge most of the cuts to get them started. It isn't the most comfortable way to start a cut; however, I am comfortable doing it when I have to. I stopped short of the corners and finished them will a Japanese style pull saw. Some of the corners didn't need more than a light sanding, some needed a file.

Saturday, March 25, 2023

I learned Sketchup

I recently came into possession of an old Craftsman radial arm saw. I wasn't looking for one but when my father-in-law recently passed away I inherited his. He'd had it on a homemade stand made of 2x4's. It was serviceable but since it was easier to transport the saw without the stand I didn't take it. Also, since this will not be an everyday tool I cannot dedicate space in my primary workshop for it. This means I need a mobile base for a fairly heavy tool.

A friend of mine - we'll call him "Dave" to protect his identity - is a new woodworker and is still building his shop. When he was looking at buying a contractor table saw I did some research looking for home made mobile bases. He ended up buying one with a mobile stand and didn't need a homemade stand but I remembered this stand from my research.

It's a cute little cart and fits a lot of the criteria I was looking for:

- Mobile

- Smallish foorprint

- No fussy build details

- Stable

What I wanted to mention here was, "I learned Sketchup". If you are reading this you've probably already heard of Sketchup. If you haven't, Sketchup is a 3d modeling tool with lots of features. If you are somewhat technically literate and maybe have some 3d design background it is quick and intuitive to learn. I made the above model after watching 40 minutes of videos and then another 5-10 hours of playing with the tool.